Vertical injection molding machines with massive-built full-hydraulic or double-stage clamping unit. Clamping force ranging from 1000 kN through 8000 kN.

FIFO-type injection units with optimized head, efficient screw/chamber temperature control and short injection nozzle, suitable to process all compounds. Injection volume between 500 ccm and 10000 ccm.

Side ejectors for efficient mold opening and external ejection devices for part detachment and handling.

Proportional hydraulic control to maximize performance with up-to-date drive to optimize energy consumption.

PLC control and touch screen HMI with state-of-the-art operator software for full process parameter control.

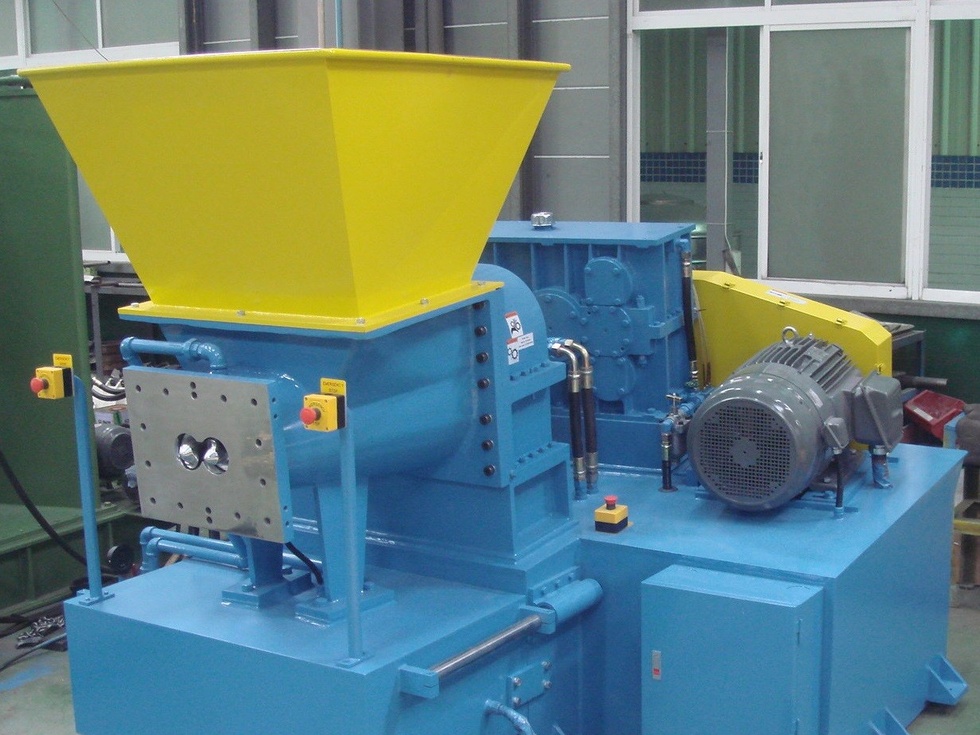

Horizontal 4tie-bar injection machines with direct, full-hydraulic clamping unit, optimized for fast cycles. Clamping force up to 5000 kN.

FIFO-type injection unit with fix injection chamber and short nozzle to avoid scorch. Forced feeding by large roll feeder.

Central and side ejectors for multiple mold plate opening. Magnetic heating platens for fast mold change.

PLC control and touch screen HMI with state-of-the-art operator software for full process parameter control.

C-frame machines with clamping structure giving unlimited access to the molding area from 3 sides, thus perfectly suitable for joining extruded profiles. Clamping force from 150 kN to 800 kN.

Screw+piston injection unit design with precise dosing. Injection volume between 100 ccm and 600 ccm. Available with silicon stuffer.

Dedicated injection unit specially designed for TPE.

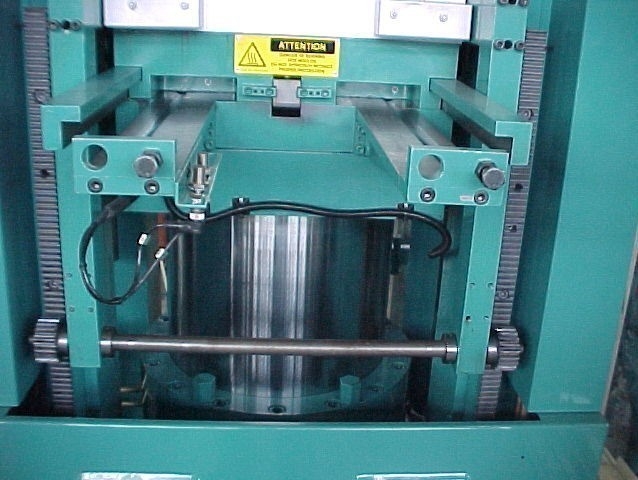

Compression molding machines with 4tie-bar, full-hydraulic clamping unit design. Clamping force from 800 kN to 4000 kN.

Heating platens with precise temperature control and strict tolerance. Hydraulic unit with proportional control.

Control by PLC with touch screen HMI and user friendly operator software.