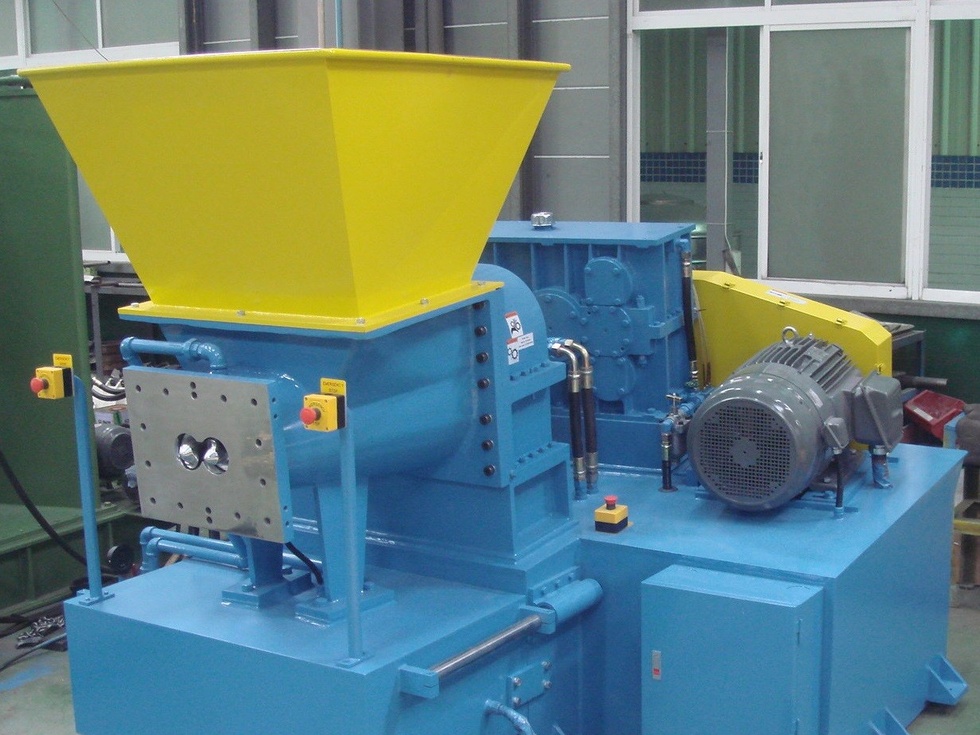

Cold feed extruders with standard and vacuum design, ensuring optimal compound processing and production performance.

→ screw diameter from Ø 30 mm to Ø 150 mm

→ high-quality gearbox & heavy-duty bearings

→ large feeding roller on screw

→ appropriate temperature control by multiple TCUs

→ extrusion head blocking device with manual or hydraulic opening

→ touch screen HMI panel with operator sofware for full parameter control

→ possible application of gear pump to increase performance with integrated control

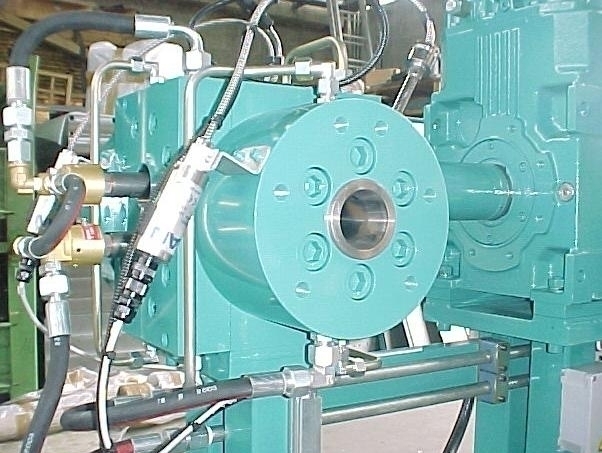

Heavy-duty gear pumps for the improvement of precision and performance in rubber and silicon extrusion.

→ chamber & gear design studied to work in severe conditions and to enhance production

→ high-quality, long life gear bushings

→ machine structure with proper support and drive

→ gear pump speed in closed-loop control with extruder

→ pump volume from 60 ccm/rpm to 920 ccm/rpm, according to extruder size

→ HMI panel with proper software for process parameter control

Machines available for a production volume from 90 kg/h through 1000 kg/h.

Complete extrusion lines with curing ovens for extruded profiles or tubes.

Shock ovens

→ short (1,5 m) or long (3 m) version

→ electric or IR heating with up to 350 °C working temperature

→ stainless steel tunnel construction

→ stainless steel rollers with inverter drive

Hot air curing tunnels

→ high-efficiency heating components & heat distribution for temperature uniformity

→ stainless steel tunnel construction

→ automated conveyor tensioning & speed control

→ overheat protection

Microwave curing ovens

→ automated, continuous microwave adjustment for stable energy output

→ high-efficiency magnetrons

→ glass-fiber reinfoced conveyor with teflon coating

→ proper protection by water curtain system

Salt-bath curing lines

→ spraying & multiple dipping tank modules in stainless steel structure

→ salt dissolving oven with adjustable electric heating & salt recycling system

→ washing & cleaning module in stainless steel structure with circulating pump & chiller

→ cooling tank with adjustable air nozzles

→ double touch screen HMI with operator software for process control

Layout of the production line according to the specific need.

Example of the RKN90L extrusion line: