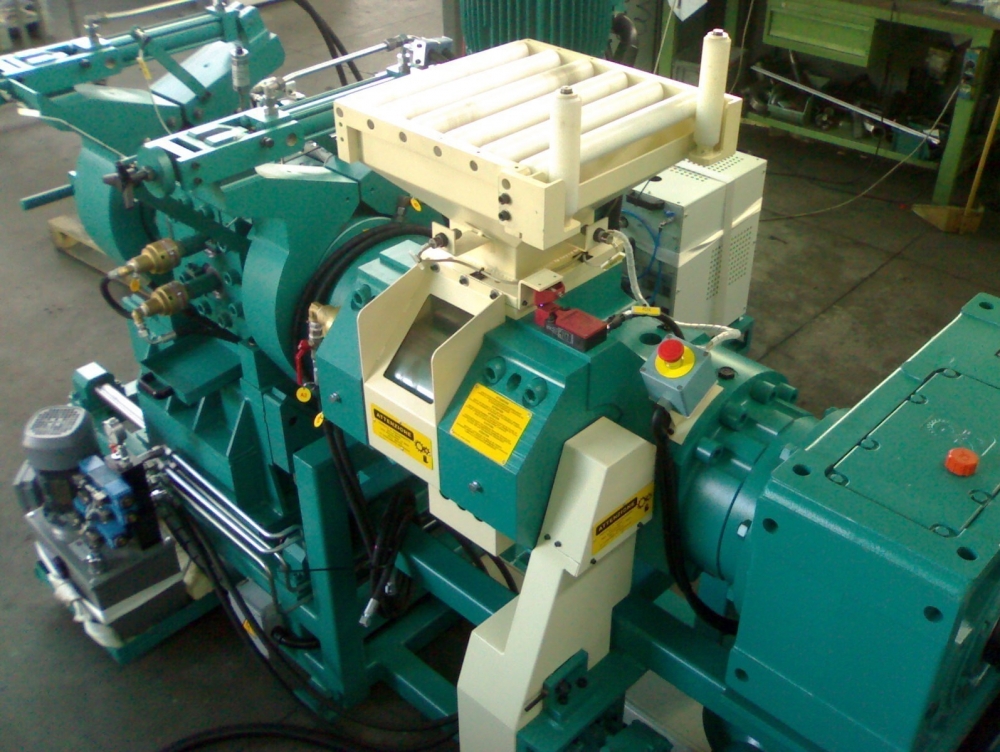

Strainers for in-line or off-line compound screening.

→ large feeding screw design with hopper

→ heavy-duty gear pump

→ single or double screening head with automated C-clamp for head opening/clamping

→ automated gear pump detachment from feeding screw for easy chamber cleaning

→ automated head detachment from gear pump for easy head cleaning

→ touch screen HMI operator panel with state-of-the-art software for process control

Machines available for aproduction volume from 100 l/h through 2000 l/h.

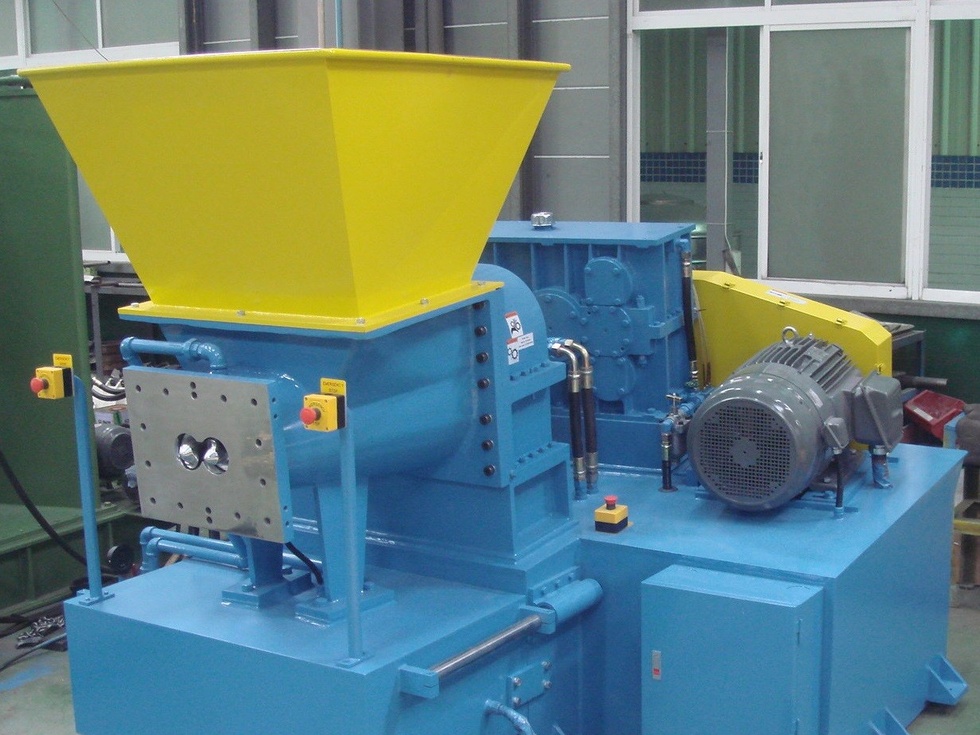

Conical twin-screw design for compound processing in-line or off-line use in mixing rooms.

→ large hopper, suitable for feeding directly from the mixer or a skip conveyor

→ appropriate screw design with cooling for efficient compound processing

→ chamber detachment for full access to the screws to allow easy cleaning

→ inverter drive for optimized power consumption

→ application of gear pump with detachment to allow easy and fast compound change & chamber cleaning

→ batch extrusion die in customized shapes

Machines available for production volumes from 250 l/h through 2500 l/h.