Machinery

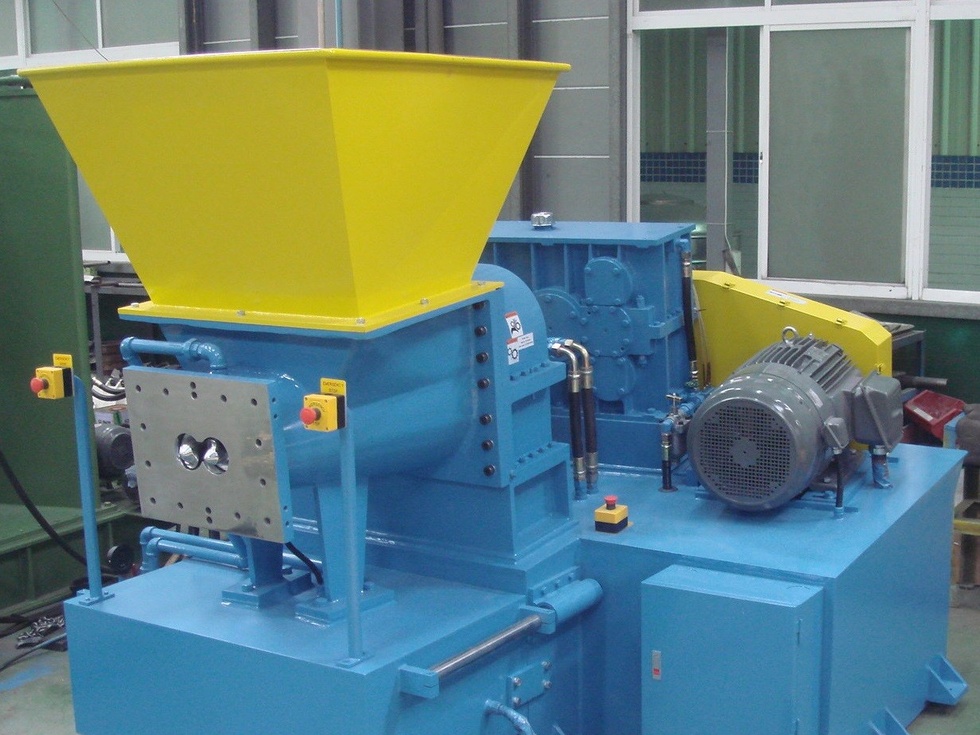

RKN offers advanced machinery for mixing and screening rubber and silicon compounds. These machines reflect the most innovative processing solutions and enhance customers' competitiveness. The development of new techniques joined to the passion to create efficient and reliable machines make it possible to offer a wide range of dedicated equipment such as

→ strainers with heavy-duty gear pump for compound screening

→ conical twin-screw kneaders

RKN offers a wide range of machines for rubber and silicon extrusion, available with standard or vacuum screw design.

The extruders might be equipped with gear pump heads for highest extrusion precision and dimensional stability. Single machines as well as complete equipment for single or multiple co-extrusion lines are available.

The spectrum includes high-performance curing tunnels for complete extrusion plants. The proposals combine quality and value, resulting in high competitiveness. Equipment with different vulcanization techniques include:

→ shock ovens with hot air or IR heating

→ hot air tunnels with electric or gas heating in modular design

→ microwave lines

→ salt bath vulcanization lines

RKN offers technologically advanced machinery for injection and compression molding of rubber goods. The range of products include

→ vertical injection molding machines

→ C-frame injection machines

→ horizontal injection molding machines

The supply of innovative technical solutions, among them most modern molding systems and compound saving techniques is ensured by appropriate engineering. Complete production proposals are made based on the most suitable and cost-efficient solution.

The supply stretches to customized turn-key projects and provides machinery solutions with the possibility of process automation, including special machine features such as insert preloading & loading devices, mold sliding tables, part ejection systems, mold surface cleaning equipment.

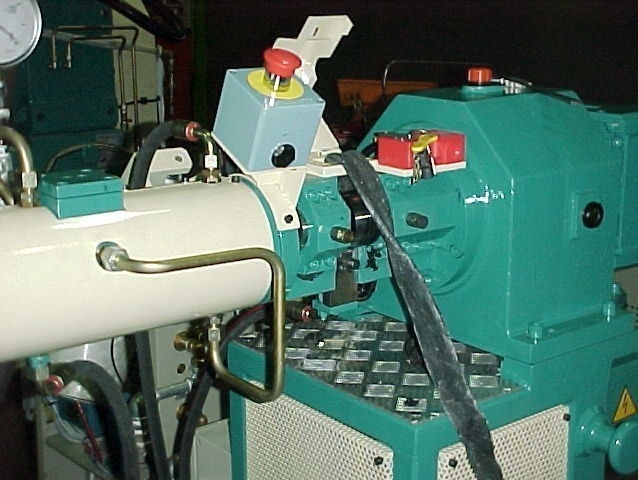

RKN offers state-of-the-art devulcanization technology for the recycling of scrap rubber. The technology is based on the most reliable thermo-mechanical process which combines the advantages of:

→ continuous manufacturing, resulting more convenient and industrially stable compared to batch production

→ selective breaking of compound crosslinks with high efficiency without use of any chemical additive

→ excellent product quality with unmatched mechanical properties.

Thanks to the excellent mechanical properties of the compounds processed with this technology, the devulcanized compounds can be used as polymer or filler for the production of a broad range of technical rubber products. Their use might have a crucial share in compound cost-optimization and solve some environmental issues related to scrap disposal and related costs.